Bob's illustrated Type study of Bailey bench planes. Part 2 The user's models years

Continuing on our illustrated Type study list

Part 1 The Collector's model years Type 1 to 7 can be found here

TYPE 8 Stanley 1899-1902

All features of Type 7 except;

"S" casting marks eliminated from castings

Only one patent date left on the lateral lever 7-24-88

"B" casting marks on most specimens. B code for foundry name unknown, perhaps Birmingham?

TYPE 9 Stanley 1902-1907

Major changes

All features of Type 8 except;

"B" casting marks eliminated from castings

Patent date eliminated from lateral lever

Bailey name now cast on toe.

This relocated the model No 5 to 8 cast to the heel from the toe

New style frog and raised frog receiver. Patent dates Mar-25-02 and Aug-19-02

cast on bed behind frog

Larger sizes have been observed with a higher and arched rib in frog receiver but still no frog adj, screw

TYPE 10 Stanley 1907-1909

All features of Type 9 except;

Center rib in frog receiver enlarged and arched

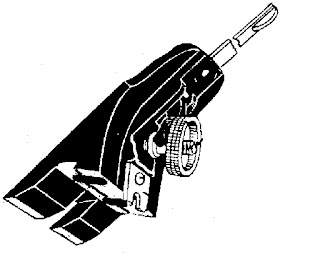

A frog adjustment screw, first offered on the Bed Rock planes, is now added. This is located below the frog, and engages a fork that is screwed to the frog. A turn of this screw will move the frog forward or backward, depending on the direction it is turned.

So how best to adjust the frog position? Make the frog face flush with the bed rear mouth area.

These two cutaway pics from Paul Sellers shows the small range of blade advance and retraction. The more the blade is out, the less you can advance the frog. Also since the range is small, the position of the slot in the cap iron that engage the yoke, is critical for achieving proper operation. That is why when replacing the blade with after market blade/cap iron, from various other makers, you can easily ran into problems. The often repeated fix is to file open the mouth area. I rather not...

New trademark on irons starting in 1907

Change in handle design

"STANLEY" in block letters, 5/32 in high

Special trademark on irons, apparently used in 1909 only

TYPE 11 Stanley 1910-1918

All features of Type 10 except;

APR-19-10 patent date now added to previous two cast behind frog

New trademark stamped on irons starting in 1910

TYPE 12 Stanley 1919-1924

All features of Type 11 except;

All planes now equipped with a high front knob

Brass adj. nut is larger, now 1-1/4 in diameter

Minor design changes of rib structure on frog just above Adj. nut

Design change to lever cap. The lever cap has a subtle change in its shape - it is not as rounded about the edges as the earlier style is. The lever cam is a bit longer than the old - 1 3/16" vs. 1 3/32".

New trademark stamped on irons of planes. A series of logo changes are found on these planes. All 3 of the logos are the result of the merger betweenStanley Rule and Level, the tool producer, and The Stanley Works, the hardware producer. A notched rectangle, in which the word "STANLEY Stanley Works, and "STANLEY Stanley Works long-time president, William Hart. The first version of the logo has "NEW BRITAIN U.S.A.

New trademark stamped on irons of planes manufactured in 1920

The final logo, dating from 1923-1935, is identical to the second, but the "MADE IN U.S.A." line is a hair shorter than the length of the notched rectangle. These new logos are know as the "sweetheart" logo in the tool collecting biz.

TYPE 13 Stanley 1925-1928

All features of Type 12 except;

U.S. PAT

APR-09-10

Now only markings cast behind frog

STANLEY in notched rectangle now cast on lever cap

5. The later planes have a yellow background in the notched rectangle. These planes typically have the rounded iron (type 19 and up).

Another thing not mentioned in the type study is that on some examples the frogs have an orange over paint on them. When this was done is during the 20's. Why it was done is unknown. It may have been for a large customer, likeNew York City

TYPE 14 Stanley 1929-1930

All features of Type 13 except;

MADE IN U.S.A. now added to markings cast on the bed

A raised ring is cast into the bed to act as a receiver for the knob. This is to stem the splitting of the knob, about its base, which was a very common thing to occur. The high knobs (introduced at Type 12) were very prone to this, prior to the introduction of the raised ring, due to the greater leverage capable of being placed on them than could be placed on the low knobs.

Not mentioned in type study's but the bottom of the knob has a slight taper to seat inside the raised ring.

TYPE 15 Stanley 1931-1932

All features of Type 14 except;

MADE IN U.S.A. now cast on bed behind frog

Patent date marking on bed eliminated

Casting markings on the toe changed

TYPE 16 Stanley 1933-1941

All features of Type 15 except;

New trademark stamped on irons starting in 1936

Kidney shape hole now on lever caps

Casting markings on toe changed, now has a raised rib

Design change in frog receiver provides less metal between arched center rib and sides on most specimens of this type

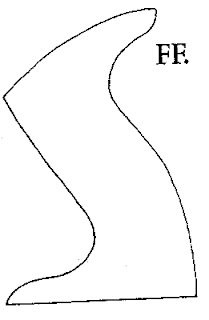

Design changes in frog provides an Ogee shaped back (on top)

Slightly raised receiver now provided for handle along with a reinforcement rib across the toe and heel edge of plane bed

TYPE 17 Stanley 1942-1945

All features of Type 16 except;

These are the war production planes, and all bets about what is and isn't proper on these examples, and those made in the years immediately following, are off. This is an area where the type study is very weak, in my opinion. But it's understandable since there are so many configurations of these planes. My observations tell me that any combination of the following features is possible for these planes. And, to make matters worse, some of the examples have the standard features (rosewood, brass) of the previous type in conjunction with some of the features of this type. This all is likely explained by the fact thatStanley

Handle and knob are hardwood stained red or painted black.

Depth adjustment now is smaller, made either of steel or hard rubber

Handles and knobs are of hardwood with dark rosewood stain

Wartime castings are noticeably heavier with thicker sides

Adj. nut maybe be a small diameter steel nut or large diameter of hard black rubber (sequence of apparition unknown)

Some specimen have been observed without the frog adj. screw or kidney shaped hole in lever cap

TYPE 18 Stanley 1946-1947

All features of Type 17 except;

Handle (tote) of new design and painted black

The large brass depth adj. nut now have diagonal knurling

Casting are lighter in weight as pre-war production

TYPE 19 Stanley 1948-1961

All features of Type 18 except;

Frog receiver design change provides an arched buttress

Rosewood handles re-introduced in 1949 have a thick varnish nearly obscuring the the wood grain

STANLEY letters on lateral lever are now read vertically

Most brass adj. nuts now have regular parallel knurling

Later models of this type C. 1958-1961 have handles and knobs of hardwood with a dark stain

TYPE 20 Stanley 1962-1967

All features of Type 19 except;

Castings are now painted blue (not japanned), although some are still japanned black, Sequence of apparition unknown

Hardwood handles and knobs have a light color stain

Lateral lever are one piece bent steel, but still has the roller at the end

Top of blade has rounded corners

STANLEY name eliminated from lateral lever

BEYOND TYPE 20

The Maroon Stanley's, from the 70s

One of the last Stanley's Made in USA, before production being shifted to England. Still look like a plane, but look at the frog surface and the lateral lever, a mere shadow of its former self...

The blue Stanley's, Made in England

The Types 8 to Type 13 are considered by most the very best users. They have all the features you need and were still well made.

Starting at type 16, with the introduction of the Ogee top on the frog, it herald the end of the solid surface frog and it is all downhill in quality from there.

Mind you some of these earliest Ogee frog can still be fettle pretty good and can gives excellent results.

The later version with a rough surface, painted frog and cheesy lateral lever are not worth crap as users.

And that is all she wrote...

Bob, who need a break from his computer. Time to crack open a cold one, cause I deserved it, my friends (with apology to Stumpy :-)

Part 1 The Collector's model years Type 1 to 7 can be found here

TYPE 8 Stanley 1899-1902

All features of Type 7 except;

"S" casting marks eliminated from castings

Only one patent date left on the lateral lever 7-24-88

Notice orientation of Pat dates, was vertical before now horizontal

"B" casting marks on most specimens. B code for foundry name unknown, perhaps Birmingham?

Notice the small size of the central rib and the B casting mark

on the back side of the lever cap

"B" Casting mark on frog.

Same location were the nib or the S mark was

Pics from Ebay

TYPE 9 Stanley 1902-1907

Major changes

All features of Type 8 except;

"B" casting marks eliminated from castings

Patent date eliminated from lateral lever

Bailey name now cast on toe.

This relocated the model No 5 to 8 cast to the heel from the toe

No 5 to 8 now have their model Nos cast on the heel

New style frog and raised frog receiver. Patent dates Mar-25-02 and Aug-19-02

cast on bed behind frog

Pic from my No 7 Type 9. Notice bigger center rib

The original type study doesn't mention this - It's about this time that the brass nuts used to secure the knob and tote to the rods undergo a change. They now have a waist to them whereas the earlier ones are cylindrical over their length.

That was in an effort to reduce the tendency of the brass cylinder to stick to the wood.The original plain cylinder brass nut for the knob and tote

The new brass nut with a waist

Pic from Ebay

TYPE 10 Stanley 1907-1909

All features of Type 9 except;

Center rib in frog receiver enlarged and arched

A frog adjustment screw, first offered on the Bed Rock planes, is now added. This is located below the frog, and engages a fork that is screwed to the frog. A turn of this screw will move the frog forward or backward, depending on the direction it is turned.

So how best to adjust the frog position? Make the frog face flush with the bed rear mouth area.

Frog back, mouth fully opened.

If the frog is not lined up with the bottom casting, the blade

is not correctly supported

Frog forward, mouth fully closed. With the frog forward, the back bottom of the blade is left unsupported and is more subject to chatter

Pics from Paul Sellers

New trademark on irons starting in 1907

Pic from Bob Kaune

Change in handle design

"STANLEY" in block letters, 5/32 in high

Special trademark on irons, apparently used in 1909 only

Pic from Bob Kaune

TYPE 11 Stanley 1910-1918

All features of Type 10 except;

APR-19-10 patent date now added to previous two cast behind frog

New trademark stamped on irons starting in 1910

Pic from Bob Kaune

TYPE 12 Stanley 1919-1924

All features of Type 11 except;

All planes now equipped with a high front knob

Difference between low and high knob

Waist area on brass nut.

Notice the un-tapered bottom part of the knob

Brass adj. nut is larger, now 1-1/4 in diameter

Type 9 on left Type 13 on right (same as Type 12)

Minor design changes of rib structure on frog just above Adj. nut

Design change to lever cap. The lever cap has a subtle change in its shape - it is not as rounded about the edges as the earlier style is. The lever cam is a bit longer than the old - 1 3/16" vs. 1 3/32".

New trademark stamped on irons of planes. A series of logo changes are found on these planes. All 3 of the logos are the result of the merger between

New trademark stamped on irons of planes manufactured in 1920

Pic from Bob Kaune

The next version, dating from 1921-1922, just has "MADE IN U.S.A" below the heart, in one line that is longer than the length of the notched rectangle.

Pics from Bob Kaune

The final logo, dating from 1923-1935, is identical to the second, but the "MADE IN U.S.A." line is a hair shorter than the length of the notched rectangle. These new logos are know as the "sweetheart" logo in the tool collecting biz.

1922-1935

1923-1935

Pics from Bob Kaune

This isn't in the original type study - Some of the lever caps can be found with the outline of the sweetheart logo cast into the backside. I've only noted one of these planes, a #5, with this lever cap. Its iron is stamped with the first sweetheart trade- mark. Another tool pal of mine, from longuyland, has seen one before. These two examples are the only ones I know of in tooldom. So far, that is.

Again, not found in the original type study - it's about this time that the backs of the cap iron are no longer blued, but are just finished like the fronts, with nothing. That bluing that Patrick Leach is talking about look like a mat greyish blue coating. I suppose it was there to help prevent rusting between the blade and its cap iron?

All features of Type 12 except;

U.S. PAT

APR-09-10

Now only markings cast behind frog

STANLEY in notched rectangle now cast on lever cap

"STANLEY

1. The lever cap is machined and finished as before, with the notched rectangle's background japanned. I believe this to be the earliest since the earliest Bed Rock planes have lever caps of the same treatment (Bed Rock lever caps always had some embossing on them, and the earliest ones have the japanned background). My experience tells me that this lever cap treatment is rather uncommon

2. The entire lever cap is entirely nickel plated, including the background of the notched rectangle.

3. The lever cap is nickel plated, but the notched rectangle's background is painted in Stanley

4. For a short period, with the lever cap nickel plated, the notched rectangle's background is decidedly reddish in color. This may due to Stanley Winchester Stanley

5. The later planes have a yellow background in the notched rectangle. These planes typically have the rounded iron (type 19 and up).

Another thing not mentioned in the type study is that on some examples the frogs have an orange over paint on them. When this was done is during the 20's. Why it was done is unknown. It may have been for a large customer, like

TYPE 14 Stanley 1929-1930

All features of Type 13 except;

MADE IN U.S.A. now added to markings cast on the bed

A raised ring is cast into the bed to act as a receiver for the knob. This is to stem the splitting of the knob, about its base, which was a very common thing to occur. The high knobs (introduced at Type 12) were very prone to this, prior to the introduction of the raised ring, due to the greater leverage capable of being placed on them than could be placed on the low knobs.

Not mentioned in type study's but the bottom of the knob has a slight taper to seat inside the raised ring.

TYPE 15 Stanley 1931-1932

All features of Type 14 except;

MADE IN U.S.A. now cast on bed behind frog

Patent date marking on bed eliminated

Casting markings on the toe changed

TYPE 16 Stanley 1933-1941

All features of Type 15 except;

New trademark stamped on irons starting in 1936

Kidney shape hole now on lever caps

Old style, keyhole

New style, kidney hole

Casting markings on toe changed, now has a raised rib

Design change in frog receiver provides less metal between arched center rib and sides on most specimens of this type

Design changes in frog provides an Ogee shaped back (on top)

Pic from Ebay

Slightly raised receiver now provided for handle along with a reinforcement rib across the toe and heel edge of plane bed

Hang hole is a user mod.

Pic from Ebay

TYPE 17 Stanley 1942-1945

All features of Type 16 except;

These are the war production planes, and all bets about what is and isn't proper on these examples, and those made in the years immediately following, are off. This is an area where the type study is very weak, in my opinion. But it's understandable since there are so many configurations of these planes. My observations tell me that any combination of the following features is possible for these planes. And, to make matters worse, some of the examples have the standard features (rosewood, brass) of the previous type in conjunction with some of the features of this type. This all is likely explained by the fact that

Handle and knob are hardwood stained red or painted black.

Depth adjustment now is smaller, made either of steel or hard rubber

Handles and knobs are of hardwood with dark rosewood stain

During the war, when brass was in high demand, the screw holding

the knob and tote are a one piece steel screw

Wartime castings are noticeably heavier with thicker sides

Frog screw adjust feature not always present

Notice thicker casting sides

Adj. nut maybe be a small diameter steel nut or large diameter of hard black rubber (sequence of apparition unknown)

Large diameter hard rubber wheel

Notice there are no provision for the frog screw adjust

Steel small adj nut. Has provision for the frog adj screw

Unknown if they all have the frog adj. screw

Some specimen have been observed without the frog adj. screw or kidney shaped hole in lever cap

TYPE 18 Stanley 1946-1947

All features of Type 17 except;

Handle (tote) of new design and painted black

The large brass depth adj. nut now have diagonal knurling

Pic from Ebay

Casting are lighter in weight as pre-war production

TYPE 19 Stanley 1948-1961

All features of Type 18 except;

Frog receiver design change provides an arched buttress

Pic from Ebay

Rosewood handles re-introduced in 1949 have a thick varnish nearly obscuring the the wood grain

STANLEY letters on lateral lever are now read vertically

Pic from Ebay

Most brass adj. nuts now have regular parallel knurling

Later models of this type C. 1958-1961 have handles and knobs of hardwood with a dark stain

Pic from Ebay

TYPE 20 Stanley 1962-1967

All features of Type 19 except;

Castings are now painted blue (not japanned), although some are still japanned black, Sequence of apparition unknown

Hardwood handles and knobs have a light color stain

Lateral lever are one piece bent steel, but still has the roller at the end

Top of blade has rounded corners

Pics from Ebay

The rounded edges on top of iron is mostly found with the

Yellow Stanley logo on cap irons

Pics from Ebay

Pic from Ebay

BEYOND TYPE 20

The Maroon Stanley's, from the 70s

Pics from Ebay

Pics from Ebay

The blue Stanley's, Made in England

This recent one Made in England.

Note the very cheesy one piece lateral adj.

Pics from Ebay

The Types 8 to Type 13 are considered by most the very best users. They have all the features you need and were still well made.

Starting at type 16, with the introduction of the Ogee top on the frog, it herald the end of the solid surface frog and it is all downhill in quality from there.

Mind you some of these earliest Ogee frog can still be fettle pretty good and can gives excellent results.

The later version with a rough surface, painted frog and cheesy lateral lever are not worth crap as users.

And that is all she wrote...

Bob, who need a break from his computer. Time to crack open a cold one, cause I deserved it, my friends (with apology to Stumpy :-)

Comments

Post a Comment